As sad as it was to say goodbye to the Gravity Nelson trailer, we were stoked to be moving in to a slightly more ‘weather-proof’ set up (to be honest, it’s more like a bunker). Dropping a 20ft container on our spot in the pocket park meant we could create a more permanent and secure site to run things from, plus we got to have a bit of fun planning out how we would make it work. All the boys were pumped to pick up the tools and get stuck in!

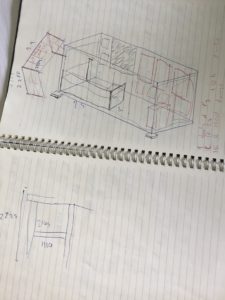

Based on a bunch of “yeah nahs”, “she’ll be right’s” and “Looks pretty good’s” plus an intricate, well thought out, technical CAD drawing pictured below. NB. the empty space on the page was left for annotations but as it turned out we just started building stuff before any notes were written down.

The engineering that went in to the design was not taken lightly. The team knew that the pressure was on to wang together something that would not only fit bikes and bike related stuff in there, but also needed room for beer and a subwoofer. The hours (maybe 2ish) of research done to maximise the physical space inside the container paid off. Research done in the size and shape of various beer bottles was also explored, this was probably the toughest part of the job. But it had to be done.

The frame was fitted entirely to the solid wooden floor of the container. We were determined not to drill in to the container itself, to keep things water-tight and keep the container in good nick in case we buggered it up and had to get “warranty”

After chuckin’ a few zip ties here and there we clad the container with marine ply. We chose marine ply completely by accident. As it turned out, it was probably the best stuff for the job. So that worked out pretty well.

Shelves and the workshop workbench were the crux of the operation and required full gas from the boys. Thankfully, there were minimal OSH nightmares and the only issues were related to sunburn and dehydration. Both issues were fully (ish) documented and steps have been put in place to avoid future incidents. Slip, Slop, Slap and wrap.

She was coming together at this stage, we were happy with the use of space and then just needed to start putting on the finishing touches. Staining the ply was admittedly unnecessary but it looks cool, so we did it anyway. Tidying up the tool wall, getting in some bike bits and cleaning the coffee machine were some of the remaining items on the to-do list.

Sustainability, durability, practicality and minimalism were in mind through the whole process. Built (more or less) in a week, the finishing touches are still being added and organising is still being done.

Watch this space for the external dress-up when we figure out what we’re going to do. Or maybe we’ll wing it…

Cheers to all that lent a helping hand, Hamish for letting us use his skill-saw and drill (which are probably toasted…sorry mate), The Nelson city council for being rad, Michael at Streatkitchen for getting stoked and mother nature for going easy on us with the weather while we were working.

Chur